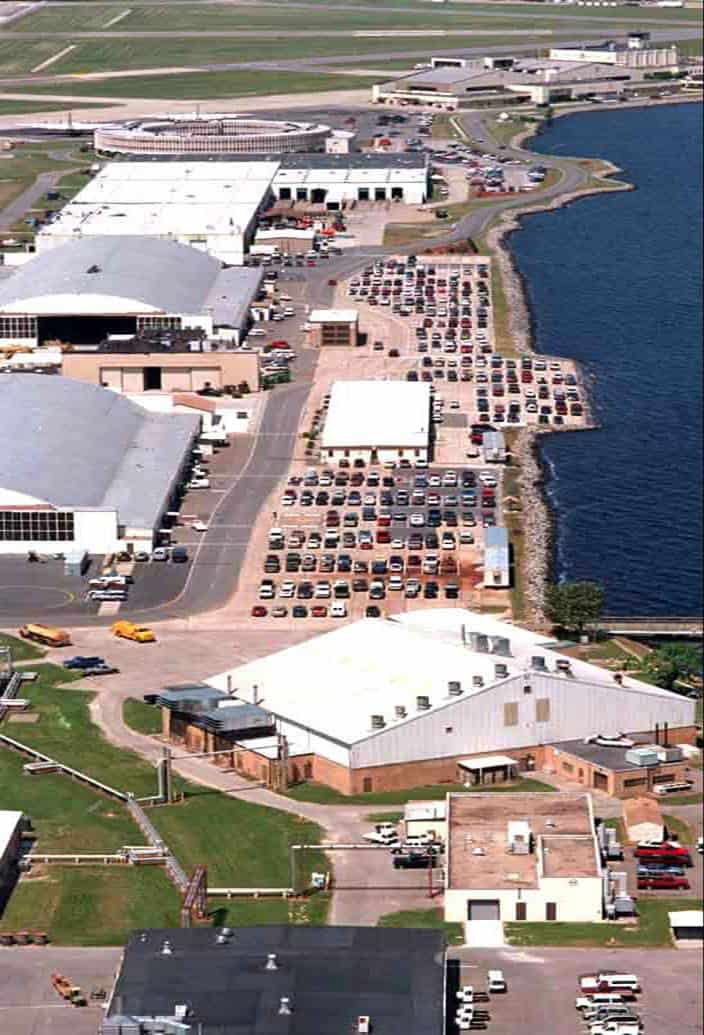

Coast Guard Aviation Logistics center

On October 30, 2008, the Vice Commandant of the Coast Guard recognized the evolution of the former Aircraft Repair and Supply Center into The Aviation Logistics Center. This event also marked the formal recognition of the implementation of the Coast Guard’s first Mission Support Center and celebrated the attainment of a major milestone in the Commandant’s Logistics Transformation initiative.

In September 1985, the United States Coast Guard awarded TAMSCO a contract to develop and maintain a Coast Guard owned/contractor operated computerized system, known as the Aviation Computerized Maintenance System, (ACMS) that would track, report, and schedule all maintenance activities on Coast Guard aircraft. This system provided the air stations with maintenance procedure cards (MPCs) and a maintenance due list (MDL) for each aircraft. It also provided the aviation program with a configuration management tool and source information for the Reliability Centered Maintenance Program (RCMP). The hosting of the ACMS was later moved from the contractor’s facility to AR&SC.

In circa 1993 the Coast Guard developed Aviation Material Management Information System (AMMIS) was introduced to the fleet. The AMMIS database tracked demand requisitions (orders) placed to the supply source, the shipment of good parts to the air stations and maintenance facility, the receipt of failed parts, their shipment to vendors or in house repair, and their induction back into the system. It also paid the vendor bills.

The two systems resulted in vast improvement over anything that preceded it but the air station Engineering Officers had two separate data bases to work; ACMS for tracking aircraft maintenance and configuration; AMMIS for ordering parts and keeping track of inventory. In circa 1995 the project to create a system that could incorporate ACMS and AMMIS into a single system was started. This project was called the Aviation Logistics Management Information System (ALMIS). An additional requirement placed on this new system was to also incorporate operational data into the system so the program would have full visibility of the status and well-being of each aircraft system. Once ALMIS was started it was found that an “umbrella” could be put over the ACMS and AMMIS data bases so they could communicate and an Electronic Aircraft Logbook which collected the operational information. (old blue sheet data) could be included. This resulted in three separate but interlinked data bases providing a multitude of information. The question became how best to use it. This is where COGNOS came into play. It is a commercial off the shelf tool designed to “mine data” from systems like ALMIS. In 2003 COGNOS was added to the ALMIS suite. It took almost ten years to get ALMIS working like it is described below.

The Aviation Logistics Management Information System (ALMIS) enables efficient, flexible, and cost-effective aircraft operations, logistics, and maintenance support. ALMIS supports data entry from the start of a flight operation, recording the flight execution, tracking aircrew events, aircraft aging, aircraft configuration, aircraft maintenance requirements, aircraft part replacements, warehouse activities, procurement actions, financial payments, and reconciliation. A suite of Coast Guard developed reports and commercial off the shelf business intelligence reporting tools are used to provide information to business managers throughout these related processes for optimal mission performance. ALMIS is a steady-state system, and satisfactorily completed the “Select” and “Control” Phases of the Coast Guard IT CPIC Process in 2002. ALMIS was approved for continued operations and investment with no major issues found. In addition, ALMIS is accredited under NIST 800-37 Security Standards for IT systems. ALMIS supports the comprehensive maintenance, operations, and logistical support of 200 Coast Guard aircraft at 28 Coast Guard Air Stations and at the Aircraft Repair and Supply Center in Elizabeth City, NC. ALMIS has 5,000 registered users that include pilots, maintainers, contractors, and senior decision makers at Coast Guard Headquarters. As a real-time operational system, ALMIS processes approximately 6,000 transactions per day. ALMIS is operated under a fully functional, four tier life cycle management process, and all releases are versioned and recorded according to Coast Guard standards. ALMIS maintains daily system backups and a fully-functional disaster recovery warm site in Martinsburg, WV. The ALMIS Configuration Control Board (CCB) governs the approval, scope, and schedule of any system changes. As the Coast Guard continues to expand and change its missions, functionality is changed or updated within ALMIS through these monthly software releases.

On an average day during 2008 the Aviation Logistics Center shipped over 700 aircraft parts; responded to over 100 technical/engineering questions; performed depot maintenance on 23 aircraft; worked an additional four aircraft for “Drop-In” maintenance; managed 180 contracts valued at $450M; had two technical support teams repairing aircraft at air stations; overhauled 400 component parts; and processed approximately 660 ALMIS transactions.

In 2005 the Coast Guard won national recognition for the return on investment ALMIS had generated. Hurricane Katrina proved it operationally. The aviation mission support system contributed significantly to the outstanding accomplishments of the aviation forces. This was noted by VADM Thad Allen, who had been the Senior Federal Official during Katrina.

Upon becoming Commandant of the Coast Guard in 2006 ADM Allen initiated plans for reorganizing and modernizing the Coast Guard mission support system. Under the new mission support organization all support activities will transition to a bi-level structure. All support services not accomplished at the unit level will be coordinated and managed through service centers. The planned consolidation of both intermediate and depot level maintenance or support will be modeled after the aviation logistics and mission support system.

It is planned to have an aviation service center; a surface forces service center; a C41T service center; a shore infrastructure service center; and a personnel service center. The Aircraft Repair and Supply Base at Elizabeth City was formally designated the Aviation Logistics Center on October 30, 2008 and retained all of its current functions. The Coast Guard Surface Forces Logistic Center, located at the Coast Guard Yard in Baltimore is scheduled to be formally designated in January of 2009.

CAPT Dennis Blackall will be assigned as the first Commander of the Surface Forces Logistics Center (SFLC) and CAPT Mark Butt, very much involved in the evolution of the aviation management system was assigned as the Commanding Officer of the Asset Project Office.

Note: The Aviation Logistics Center evolved from the Aircraft Repair and Supply Base. (AR&SB) The AR&SB was established in 1947. The history of AR&SB up to the time of transformation into the Aviation Logistics Center may be found in the “Growth Years 1939-1956” under “1947- Coast Guard Aircraft Repair and Supply Base Established.”