Jato – The Early Days

As Told By CWO-3 Jack Adams

Early one morning in 1944 the crew of a Navy PBM3C (C 86 or Charlie 86) delivered to the Coast Guard San Diego Air Station a liquid propellant rocket motor system to be used in rescue seaplane landing and takeoff experiments. A navy contract had been let to Aerojet Engineering Company by Naval Research for the infant JATO (Jet Assist Take Off) system’s use in the open sea. As delivered the entire rocket maintenance system was self-contained, its large diesel provided workshop electrical power and through a series of compressors utilized the exhaust to generate an inert gas under high pressure. It was a highly specialized rocket motor support plant for war use during invasion.

The seaplane crew were well into aircraft use of the rocket motors, both liquid and solid fueled, equipped and flown by a seasoned marine pilot, a navy chemist and a crew that today are recognized as rocket pioneers. With the Coast Guard/Navy SAR off-shore landing studies, the combination of added power from JATO into rough water takeoff seemed a win-win situation.

The liquid-fueled motor designated GALCIT1400-ALDW (Guggenheim Aeronautical Laboratory, California Institute of Technology, 1400 pounds thrust, Air Launched Droppable Water) instead of pumps, used pressurized gas to drive the combination fuels to a firing chamber through a mixed gauged spray system. The self-igniting (hypergolic) system used monoethylaniline and a mix of hydrosulfuric and red fuming nitric acid as oxidizers. No need for fuel pumps or ignition systems. Simple valves could turn the fuels on or off, a huge benefit over solid fueled once-fired-all-fired systems. A similar type of liquid motors designed by Reaction Motors of New Jersey was being used in the highly classified Northrop flying wing which in 1944 became the first rocket propelled aircraft as it flew for over 10 minutes at Muroc Dry Lake.

This was a surprise to me. The plane captain said they were out of Annapolis where Dr. Robert Goddard had a laboratory investigating rocket assist motors to catapult aircraft in short take off performance such as light surveillance planes flying from LSTs. Dr. Robert Goddard, the most notable of early rocket scientists, belittled for his rocket experiments that included supporting science fiction writers, left his studies in Massachusetts for friendly Alamogordo, New Mexico. It was the move that set the tone for rapid rocket development in California and the Far West..

Captain Bob Workman, USCG (Ret.) a former Academy pistol champion when I was coach, visited me on a trip through the D C area in late 2013 recounted some of his experiences as a pilot supporting various agencies involved in drug traffic control. I reflected that the Coast Guard worked in various ways not publicized as I had an experience with Navy JATO development during WWII that was not recounted in the annals of Commander MacDiarmid’s off shore landing program.

As an old seaplane SAR pilot Captain Workman was more than interested, suggested I write it up. I cautioned him that my memory was good but I was not to be held to the exactness of flight logs, other witness accounts or written references!

To set the stage of why an AOC in CG aviation might be of value to the Navy in cutting edge rocketry one only needs to know where growing hungry young adventurers best found their information; science fiction of course. Aviation was beginning to come into its own in the 1930’s and I was hooked. The work of the Russians, Germans, British and American pioneers in rocket propulsion sprouted several club-like groups of authors, scientists and engineers writing science fiction. Investigating among other things the answer for more power to catapult aircraft something neglected by the trained aeronautical engineers of the times who fought inertia and gravity with larger, heavier, piston engines.

To this Coast Guard ordnance man it was a dream come true, just to be near, to see the perfect nozzle exhaust, hear the roar so often spelled out in science fiction.

It all began much earlier with scientists and engineers at California Institute of Technology (Caltech) and a group that formed Aerojet Engineering Company, an R&D organization whose beginnings was with members of the American Rocket Society, whose motors, by the time the Navy came to using them at CGAS San Diego was a well established manufacturer of rocket motors and on its way to be a most important part NASA’s space race.

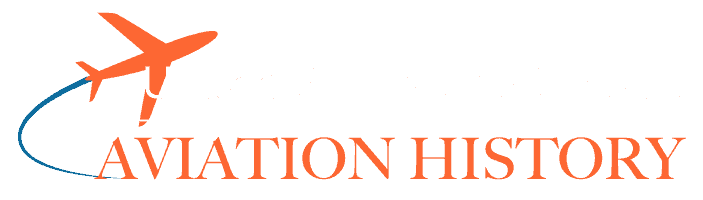

These original liquid fueled motors were designed for take-off and then dropped. Some bombers, such as the B-29, attempting to take off with full loads of fuel and bombs from short hot island runways, straining engines dangerously overheated , would be a natural place to attach two of these motors. As pictured above of a liquid motor on a PB2Y3 motors were attached to hard points under the wings. Used during the take-off run they provided that much needed extra power to get air-borne, later to be dropped safely by parachute for recovery and re-use. At an aborted takeoff they could be shut down.

An Aerojet contract problem developed as the naval air people waxed and waned about JATO rocket propulsion, close budgets threatening the contract and only providing Dr Goddard’s laboratory in Annapolis with only one test crew to follow ideas of seaplane JATO missions. It was not part of the Navy missile work in China Lake but derived support there. The Army Air Corps provided a chase plane, originally an A-20, later an A-26, rugged high speed bombers that were used for testing rocket modifications and new Aerojet designs.

The JATO program found a made to order requirement when the Coast Guard started a series of off shore tests to determine the safest and most effective method of open sea landings and takeoffs. In take off a seaplane took a series of damaging occurrences, the least of which was to achieve flyable speed before the engines were drowned.

Rough water off shore landings and takeoffs by aircraft used in SAR experiments was not new. The British had an advanced Search and Rescue (SAR) organization with heightened experience simply because WWII was the airplane’s war, had been since 1939. One item in particular was the Lindholme Gear, a cache of survival items attached to each other by nylon cord, dropped from the bomb bay, using the intervalometer to lay an outstretched up-wind line 1000 feet long, floating and drifting survival equipment down-wind to the people in the water. CGAS San Diego adopted a version converting to the USN type of dinghy and survival equipment. There were 5 elements, varying in weight that as a system weighed more than 500 pounds.

Part of the assigned Coast Guard SAR effort became central to CGAS San Diego which was to research and advance or innovate the standard survival equipment, improve delivery systems to downed aviators, train parachute riggers and ordnancemen on survival in open sea landings, providing expert knowledge of handling, loading and dropping equipment as a crew member of the SAR rescue team. The station ordnance department teamed up with the parachute loft, a chief parachute rigger, Gus Olson, that was indispensable for the proper designing, fitting and protection of droppable equipment.

Although rocketry was not a strong point in Commander MacDiarmid’s aviation experience, as a forward looking commanding officer, allowed the ordnance department head a free hand to help the Charlie 86 navy crew. That became an unreal opportunity for me as chief of the department I was allowed to join and fly as a crew member of Charlie 86, participate in and learn the operation of various rocket motors and become awash in the new science of rocket propulsion.

It was exciting watching pioneers, Navy, Aerojet, and CalTech, make their mark and be asked to help them. Note my position in the middle of the below Aerojet picture of a mix of scientists and engineers from Aerojet on a visit to CGAS San Diego when they observed their research and development of different solid and liquid rocket motors then being tested with PBYs, PB2Y3s and PBMs.

A few days after the Navy’s liquid experimental support unit and motors showed up, at about the time that the test rig was in place overlooking the sailboat marina at the south west corner of the air station, the fuel was delivered. This was no tank truck pulling up and hose to lay out. The barrels of fuel were in box cars that entered the side rails at Consolidated Aircraft accompanied by several fire engines. Behind the train’s closed and locked doors seeped smoke that not only had color but teeth, as the door showed signs of flaking! Stainless steel drums carefully sealed could not hold the combination of sulphuric, hydrochloric and red fuming nitric acid fumes. Stof N and O the Germans called it. Hypergolic systems.

The fuels allowed a simple motor design with few moving parts, a rocket motor that was inherently reliable. Pressurize the tanks of acid and aniline would squirt this mixture to meet and automatically ignite in the firing chamber, “lift off.” The rocket nozzle was the only truly complicated and cutting edge design, with the fuel being routed around the nozzle throat by metal tubing, to become a regenerative system. Actually the use of fuels traveling through pipes around the throat of the nozzle, cooling it while warming the fuel, was well known. Maintaining the operating temperature was very important to forming the perfect mathematical balance for exhaust velocity as well as preventing throat erosion. Even so, on takeoff it was a rip roaring static howling stinking toxic mess. With the wing attached motors aimed somewhat downward, the blast dug a continuous hole three feet deep each side of the airplane. On the modified PBM3C the rocket motors were attached in the engine nacelle beaver tails, the seaplane had a nose high attitude prior to getting on the step, thus the nozzle stream dug the deep holes.

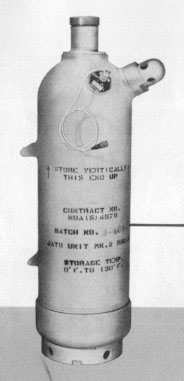

A beautifully fashioned machine showing the three spheres, firing chamber and nozzle, simple, effective, setting the standard for what became extra-terrestrial flights.

At the beginning of the off shore landing trials, Commander MacDiarmid took over as test pilot duties from test pilot Marine Capt. Bill Gore. But the liquid motors, in every day operations presented too many field use problems. On one landing the right wing unit broke from one of its attachments presenting problems as the acids sprayed about burning into the aluminum as well as making it virtually impossible to handle in the open sea. Not exactly what the mission called for.

Trial and error, photographs and analysis of data, MacDiarmid’s work had begun, a careful study of offshore landing technique under all circumstances, for which he was to earn the DFC. JATO experiments were second to his program, but became the support for further JATO study.

The test seaplane, a Navy PBM3C, was fully weaponized and combat ready, a bit different from the PBM5 used for SAR work. North Island Naval Air Station put me through Air Combat Crew training as well as open sea hard hat diving and explosive handling for which I was grateful. Further navy training made it possible for me to continue with the Navy Test Team.

The GALCIT1400ALDW was packed up and trundled off to other work, notably the before mentioned Northrop flying wing for which the GALCIT1400 was fitted. Also of interest was its installation in a zero-launch P51 with the rocket motor in the tail, rumored as an answer to the Messerschmitt 163E. Performance was superior but again the fuels created almost insurmountable problems. The Navy opted to go solid propellant for JATO.

It was a joke among the navy test crew of how the solid JATO was manufactured given all the wartime restrictions in the use of critical metals and chemicals. A standard diameter pipe used as oil well casing was readily available, a steel, of sufficient strength for firing chamber pressure and of a nominal diameter to fit the 1000 pound thrust for 14 seconds, an engineering requirement. A cap at one end, nozzle at the other, hole to accept the igniter, some thread making and pour a mixture of potassium-perchlorate and tar-like goop for propellant, voila, Jet Assist Take-Off. It is hard to remember all the trials for decent propellants that did not explode if not burning correctly but there were a few. The unit was called 14KS1000. It was generally known as “old smoky” as it generated a huge cloud of smoke if burning properly. It did produce the advertised thrust.

The JATO bottle attachment to the aft hatch on either side of the seaplane was the latest and most successful of several points to hang the motors

People kid a lot today about duct tape, which is the universal item of choice for repair, mend anything. So it was at Aerojet. The propellant poured into the casing was firm and acted nicely at cool temperatures, but tended to slump at warm or badly cracked in the cold elements of high altitudes. Handling, rattling loose fuel in shipment or stowage in an aircraft rendered the rocket motors unsafe. Burning of solid propellant is simple, ignite the face and let it burn uniformly on that face. The face presented is established as the proper pressure to provide the useful flow through the nozzle. Slump presents a greater face, quicker burn rate and higher pressure, cracks allow multiple faces to burn simultaneously, leading to explosive forces in the firing chamber. Mixes with stabilizers helped, but were not totally reliable. Finally a good R&D man made a mold, poured the propellant, then wrapped it with duct tape. Like a cigarette it now stayed in shape. The January 1986 CHALLENGER shuttle disaster is an example of what can happen when the propellant is not burned properly. The culprit, called a booster rocket, was really only a ‘S’ JATO.

Ordnance tests on the AS 1000 proved that any ammunition of .50 caliber or less, even if penetrating the casing, would not cause a high order explosion but there was an occasional detonation from 20 mm ammunition. All this was done by a hard working Aerojet group in Azusa, California, producing “quick and dirty” R&D that became excellent wartime equipment.

The Navy team’s next big requirement of any significance was to check the use on the JRMs, those large Martin JRM cargo seaplanes named the MARS that became the air supply logistic element between San Francisco, Hawaii and major Pacific islands. The Caroline Mars, a JRM-2, later broke the world record for passenger lift by carrying 269 men from NAS Alameda to NAS North Island, San Diego. They were large aircraft.

The Philippine MARS, the newest of the fleet of 5 operating in 1945, was to be tested with six JATO. The biggest need was to get on the step, especially in calm waters. Often, to facilitate take off from NAS Alameda, California, with a load of approximately 32,000 pounds, high speed rescue craft would create a wake in front of the seaplane, not only assuring a path free of logger-heads and other dangerous obstacles but creating a rough surface to help the boat shaped hull to “break suction” (surface tension) as the old timers would say.

The emphasis upon size was demonstrated when the refueling trucks arrived on the morning of the trials. Carrying 1,500 gallons of fuel each 10 trucks were eventually used. It was impressive but not nearly as much as the inside space when we finally went on board. The JATO had been installed earlier. Although Capt Gore usually flew JATO flights the Alameda crew were to take over this flight. I was on the flight deck near the engineer’s position, a fine place to observe cockpit activity during this history making flight.

The takeoff was without incident. A careful taxi to an open area in San Francisco Bay, turn into the wind, the engines full power created or pulled that huge hull to flying speed prompting vibrations that shook the instrument panel enough to make the gauges hard to read. JATO was smooth, it was reported that takeoff was reduced about half, equaling our experience even with high altitude and very hot runways.

In conclusion, rocket motors for aircraft quickly disappeared when jet engine development did away with piston engines, providing a safer form of transportation. Only for special circumstances are JATO or RATO units used today, often for a spectacular display of short takeoff at air shows or on expeditions where the rockets provide an added safety.

Remember the saying, what goes around comes around? Imagine my surprise, in the 1980s, when as a consultant to companies building forest fire fighting systems into WWII aircraft, I saw the Philippine Mars majestically flying on a forest fire, a “scooper” similar to the PBY, where the aircraft settled in high speed taxi while scooping lake water for the internal tank system, to mix as retardant then drop upon a fire!