The Cape Christian North West Territories Canada C-130 Crash!

Captain Art Wagner USCG (ret)

While at ARSC as the Chief of the Engineering Division, I was called upon for some zany missions. One of them was to proceed to the CG LORAN Station Cape Christian, Northwest Territories in Canada, and act as the Senior Accident Investigation Officer for the crash of C-130B CGNR 1345. And, Oh, by the way; see if you can get the bird out before the winter sets in.

I loaded my gear aboard an Air Station C-130 piloted once again by old friend Dave Bosomworth, and of we went. Even though it was only October, things were turning colder by the day up there.

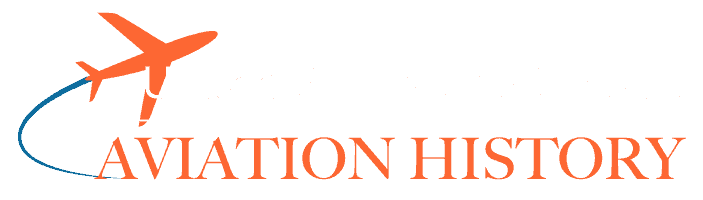

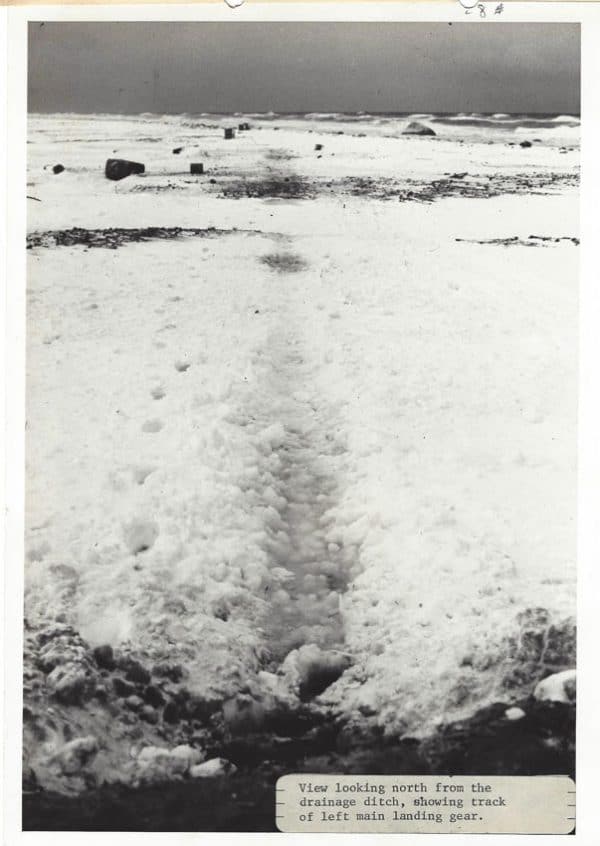

The 1345 pilot was not a Navy-Trained man and had no appreciation of Airspeed/Attitude and Power/Altitude constant angle of approach. He made the mistake of dragging in the aircraft on landing at the 3,000 ft ice runway, instead of the tried and true carrier approach of a stable steep glide slope angle. He ripped off the left MLG when it struck an ice berm at the end of the runway and slid down the length, essentially closing the “field”. Using a bulldozer, the station dragged the A/C off to the side, enabling us to land with our bird. I let the Safety types go do their thing, and see what could be done to recover the bird.

Low Pass to Check Out Conditions

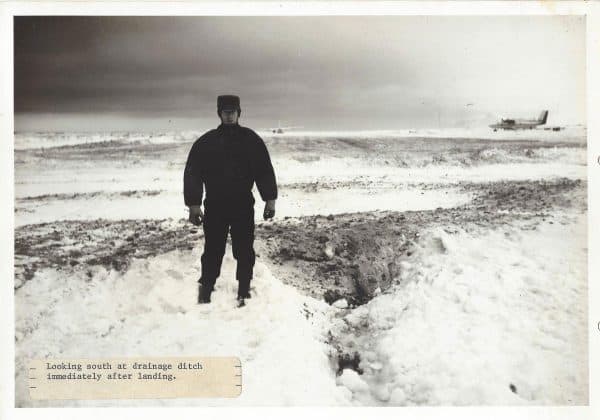

Damage was quite extensive, with the left rear main mount torn loose from the fuselage and the large belly radome (for the doppler radar navigator) was torn open. There were some cracks in the MLG –to-rear-wing-spar beam

Results of “Dragging it in”

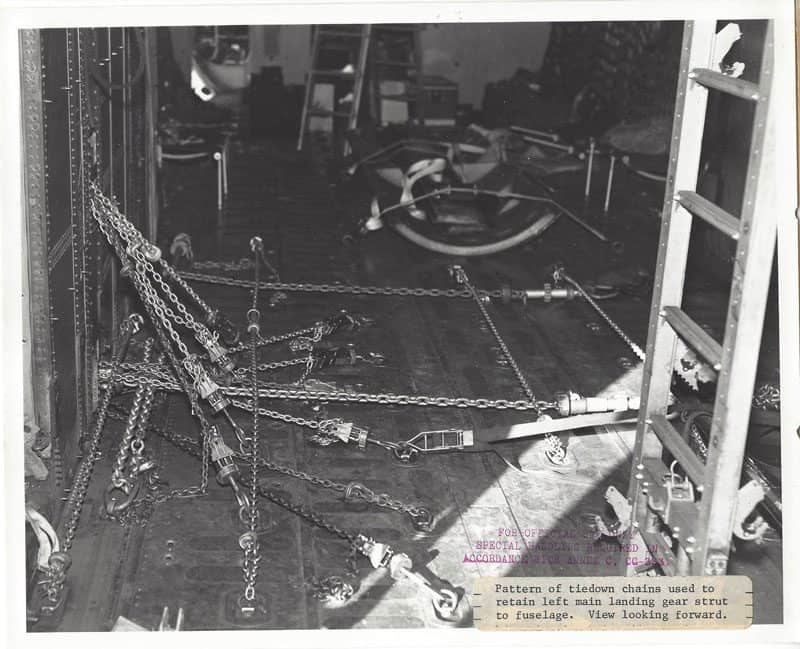

A sharp AM1 suggested that we remove the outer doors, deflate the strut, chain it through the inspection window, and fly it out unpressurized to Thule, Greenland. It was unprecedented, to say the least, but sounded workable. Some inspections and a few calculations on my part, and I approved scheme. Must have been the riverboat gambler in me. But there was more damage than just the dislodged strut. What to do with the hole in the radome and the cracked beam? The sheet metal guys rummaged around the LORAN station and found some stove pipe, split it open and screwed it to the bottom of the aircraft to cover the hole in the belly antenna – and then sealed the edges with bathtub sealant.

I called the Chief of Aeronautical Engineering in HQ and told him what I planned to do. He graciously said, “Do what you think is right, Art” knowing he could never authorize what we were about to do, but no one wanted to have a frozen monument of a C-130 at Cape Christian.

Working conditions got worse by the day, but as usual, our air crew, station crew, and pilots all pitched in to make it happen.

Not the Best of Working Conditions

Temporary repairs Made

The station once again bulldozed a path, and we dragged the bird back to the runway

Away We go headed for Thule

We had some agonizingly unsuccessful tries at starting number 2 engine, and we were beginning to worry. There was only about 4,500 lbs of JP-4 in each tank, and no one was interested in a three-engine take off. Another enterprising AD opined that he thought the feather valve in the MGB was frozen in the feather position. As soon as the engine was turned over, MGB pressure caused the prop to go to feather. He climbed up on the nacelle, took off a panel, and had the pilot roll over the engine while he beat on the outside of the GB over the feather valve with a ball peen hammer. It worked.

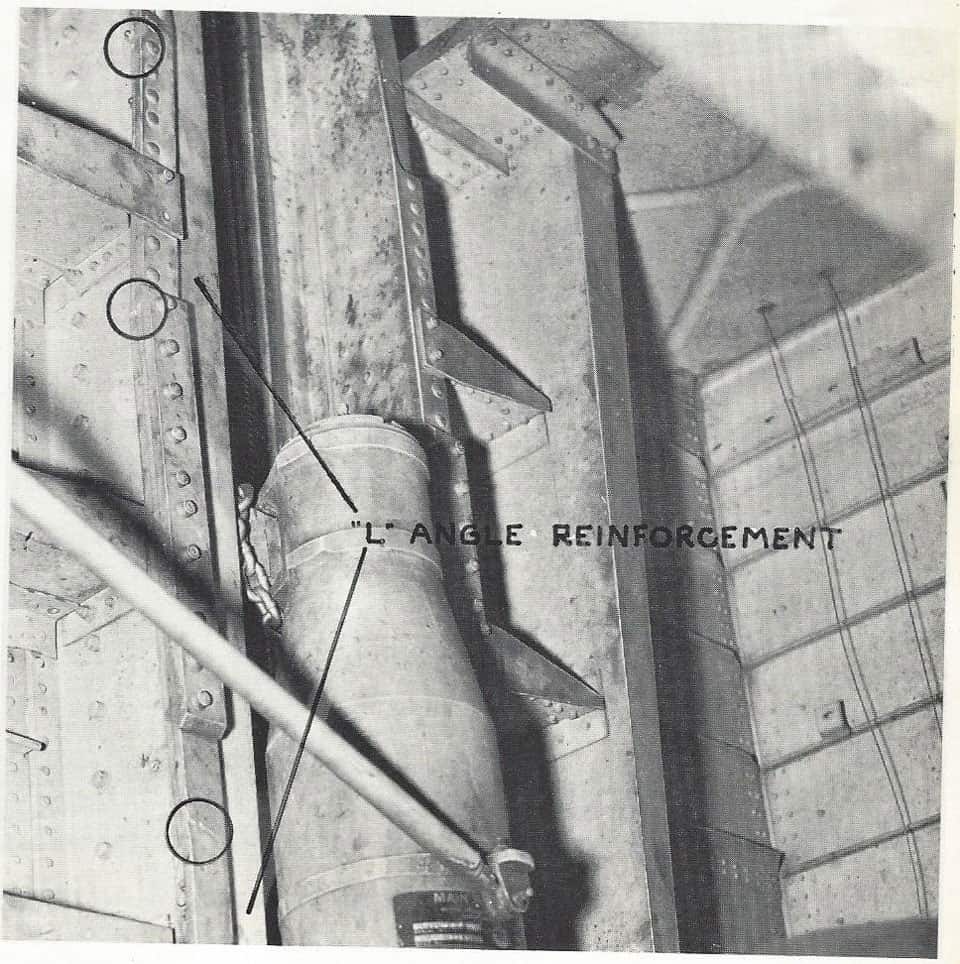

We made it to Thule, and the Air Force graciously let us use a hangar and this afforded us the opportunity to go over the bird in more detail. Unfortunately, we found that the cracks in the floor-to-wing beams had widened. Luckily, the AF had an old 50 gallon BBQ pit supported by crossed steel angle iron legs in the hangar. We appropriated the angle irons, and doubled up the beams with heavy bolts.

The MLG/Wing beam reinforcement we made from a BBQ drum at Thule

From there, we flew slowly, unpressurized, from Thule to Sondestrom, Greenland, Goose Bay Labrador, Elizabeth City NC, and to Warner Robins GA for repair. Upon arrival, the USAF Colonel shook his head and said no one in the AF would have authorized such a flight. I told him no one in the CG would have either.

At a party, Air Station’s Fred Merritt told me I was jeopardizing my career by taking such risks (There many other crazy recoveries and unorthodox designs to accommodate our missions) and I replied, “That is why they paid for me to get a Masters in Aero Engineering”.

Me and an Eskimo friend who gave me a neat knitted wool cap